Our Recover™ partnership

Learn more about our partnership with Spanish-founded company Recover™ and how it supports our Primark Cares commitments.

The partnership

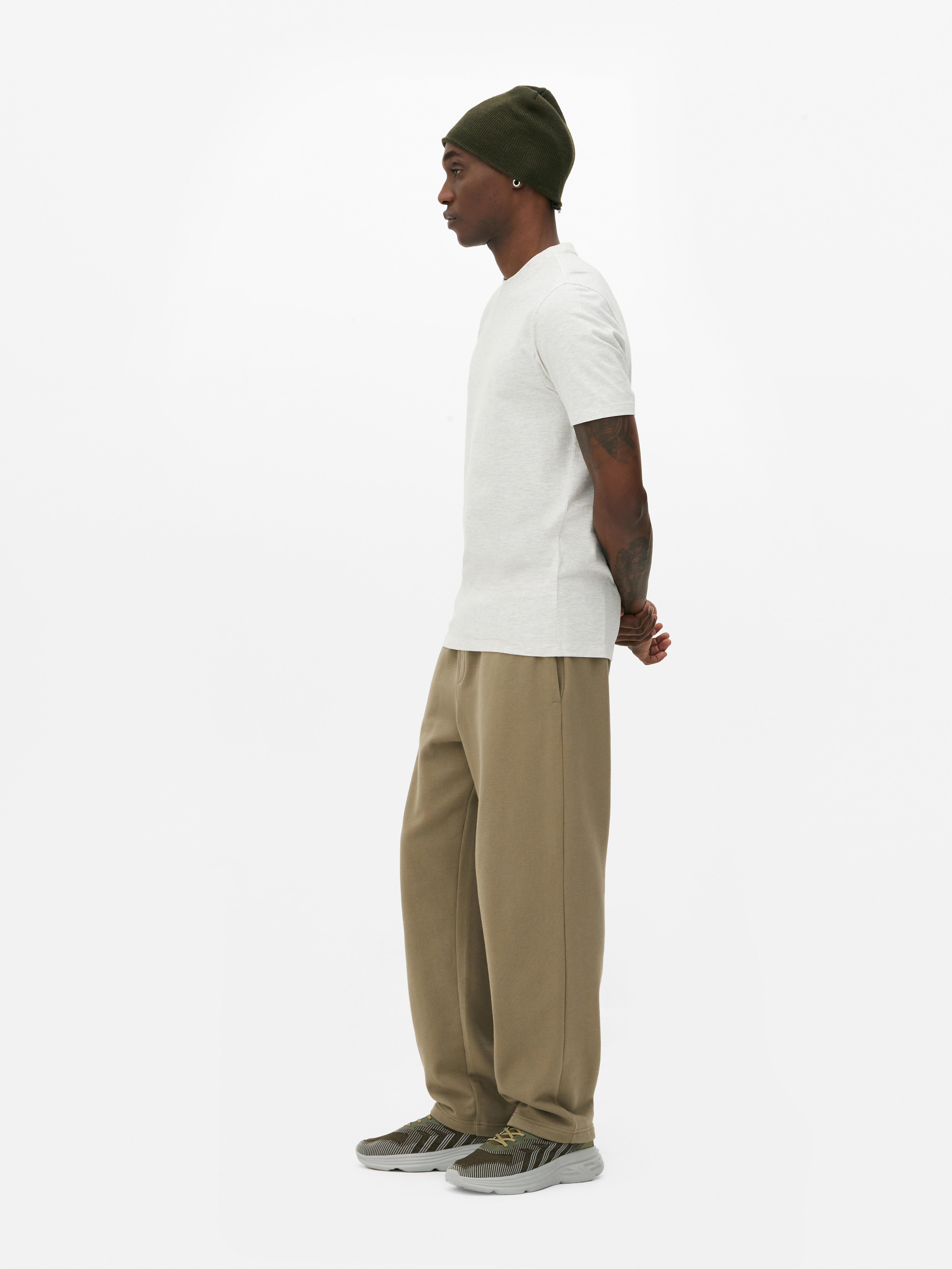

Since 2020, Primark has been partnering with Recover™ to use more recycled cotton in our clothing. This supports our Primark Cares commitment to increase the use of more sustainably sourced and recycled materials in our clothes. Our shared commitment to circularity and innovation is having a real impact, and we're proud to continue our journey together to make more sustainable fashion accessible to all.

About Recover™

Recover™ is a materials science company that is reimagining the clothing industry by transforming textile waste into low-impact, high-quality recycled cotton fibre and cotton fibre blends.

Innovative technologies like Recover™ have the capability to turn textile waste (post-industrial waste and used garments) into high-quality recycled fibres that can be used again to create new pieces, closing the loop on fashion.

The Recover™ process

The fibre used in our collection of Recover™ clothing is a recycled cotton that comes from post-industrial waste. Post-industrial waste is textile fabric waste from garment manufacturing, also called clips or scraps.

Recover™ turns old textiles into new fibres using a mechanical recycling process. First, the fabric waste is cut up and shredded into tiny fibres. These can then be mixed with other fibres, like cotton from the Primark Cotton Project, and spun into new yarn. From there, it’s made into fabric that can be used to make clothes. The whole process is managed by a team of experts in Recover's™ dedicated fibre laboratories.

The impact of recycled cotton

Using recycled cotton from Recover™ can help save resources compared to traditional cotton. For every 1kg of recycled fibre made, Recover’s data shows potential savings of:

100% less water

93% fewer CO₂ emissions

99.9% lower water pollution (eutrophication)

96% less energy

100% less land use

These figures are based on Recover’s production in Spain and Bangladesh, as reviewed by EcoReview (2022, 2025), and may vary depending on where and how the fibre is made.